RAYMAX is one of China's best press brake manufacturers, having professional information on CNC sheet metal brakes. This article mainly introduces the operation of the E21 CNC system of the press brake bending machine, which is used to guide the user's operation. Everyone can read through this article and master the essentials when purchasing or before using it.

The E21 system provides complete software control, but there is no mechanical safety protection device for the operator or the machine tool. Therefore, when the system fails, the machine tool must be able to provide the operator and the external protection device of the machine tool.

1. Product introduction

This product is equipped with a press brake machine dedicated numerical control device which is applicable to various users. On the basis of ensuring work precision, the cost of numerical control bending machines is reduced significantly.

Features of the E21 system:

- Positioning control of back gauge.

- lntelligent positioning control.

- Unilateral and bidirectional positioning eliminates spindle clearance effectively.

- Retract functions.

- Automatic reference searching.

- One-key parameter backup and restore.

- Fast position indexing.

- 40 programs storage space, each program has 25 steps.

- Power-off protection.

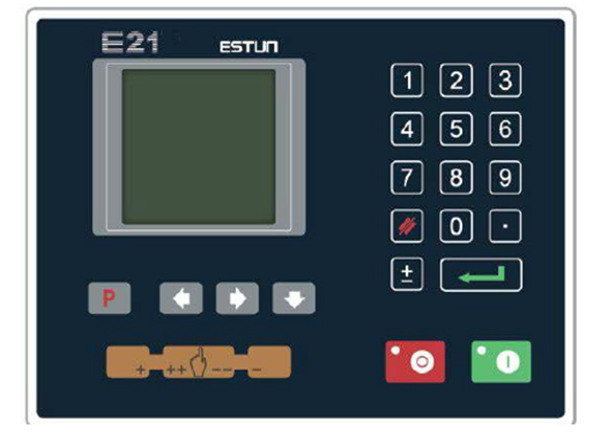

2. Operation panel

The operation panel is shown in Figure 1-1.

Figure 1-1

Table 1-1 Description of key functions

| Key | Function description |

| Delete key: delete all data in the input area on the left bottom of the displayer. | |

| Enter key: confirm the input content. lf no content is input, the key has a similar function to the direction key |

| Start key: automatic start-up, top left corner of the key is operation indicator LEDs. When the operation is started, this indicator LED is on. |

| Stop key: stop operation, top left corner of the key is stop indicator LED. When initializing normal start-up and no operation, this indicator LED is on. |

| Left direction key: page forward, cursor remove. | |

| Right direction key: page backward, cursor remove. | |

| Down direction key: select parameter downward. | |

| Function switch: switch over different function pages. | |

| Symbolic key: user input symbol, or start diagnosis. | |

| Numeric key: when setting parameter, input value. | |

| Decimal point key: when set up parameter, input decimal point. | |

| Manual movement key: in case of manual adjustment, make the adjustment object move in a forwarding direction at a low speed. |

| Manual movement key: in case of manual adjustment, make the adjustment object move in a backward direction at a low speed. |

| High-speed selection key: in case of manual adjustment, press this key and press |

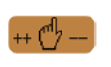

3. Displayer

E21 numerical control device adopts 160*160 dot matrix LCD displayer. The display area is shown in Figure 1-2.

Figure 1-2 Display area

Title bar: display relevant information of the current page, such as its name, etc.

Parameter display area: display parameter name, parameter value, and system information.

Status bar: display area of input information and prompt message, etc.

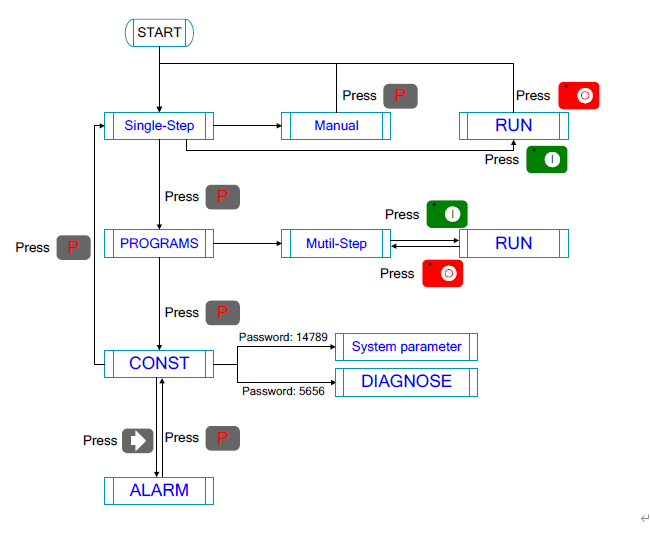

4. Basic operation procedure

The basic switch over and operation procedure of the device is shown in Figure 1-3.

Figure 1-3