Hydraulic Press Brake

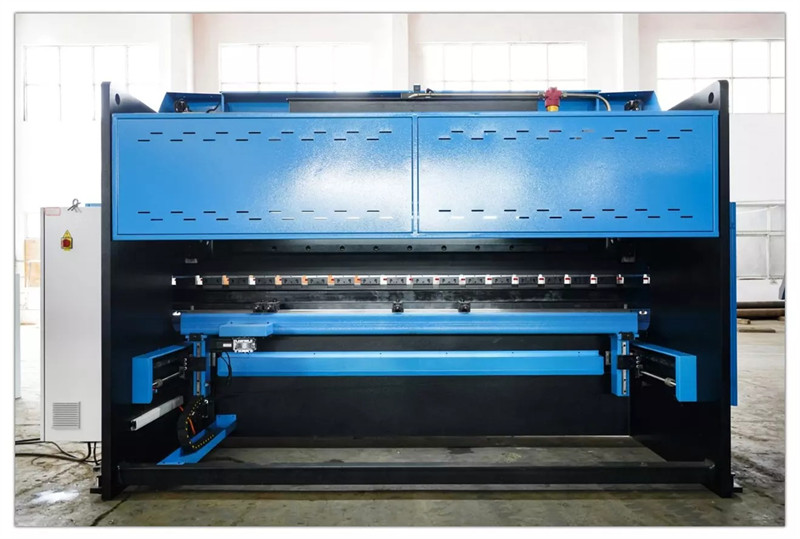

Hydraulic press bending machines are the machines used in industrial purposes mainly for the bending of sheet metal products. It forms predetermined bends by clamping the workpiece between a matching punch and die. The material is placed over a V-shaped die and pressed into from above by a punch. These CNC sheet metal benders can bend simple and complex parts, and they are used in a variety of industries ranging from automotive and aircraft to housing and cabinets.

A sheet metal press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. Whenever there is a need for bending metal panels, a press brake is essential, which makes them very common in job shops and machine shops. A hydraulic press brake machine is typically narrow and long so that large pieces of sheet metal can be bent by it. A CNC hydraulic press brake machine bends sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die. The metal may be bent several times by a press brake until the desired form has been achieved.

A hydraulic press bending machine is a piece of manufacturing equipment that is used to bend sheet metal. These CNC sheet metal brakes for sale provide the reliability of operation, low cost of production, and ease of performance. Unlike conventional notions, Zhongrui’s CNC hydraulic press brakes are compact, energy-efficient, noiseless operation, minimal vibration, easy adjusting, high-security level, etc. The frame construction features stress-relieved, heavy, rolled steel plates and is designed for optimum rigidity and cross-system alignment.

As the top 10 professional press brake manufacturers, Zhongrui has over 18 years of experience engineering and building hydraulic press bending machines of the highest quality – this means our CNC sheet metal brakes for sale are built to last. Our sheet metal press brake machines are made to handle years of precision used in the harshest production environments. We are proud to build heavy-duty, rugged equipment that allows our customers to get the job done every day.

How does Press Brake Machine Work

Hydraulic press brakes have better control when inching down and setting up for your bend, they also can return to the top at any time. CNC hydraulic press brake machine’ rotary hydraulic cylinder turns the eccentric shaft by means of rigid mechanical linkage to both ends of the ram, distributing power equally over its full length. This basic power principle offers the operational control and safety of the hydraulic principle plus the rigid ram alignment, accuracy, and operating speeds of the mechanical press brakes.

CNC sheet metal brakes are able to adjust the status of the upper cross-beams, but this provision is also referred to as the top dead center. At the time of pressing the pedal or button, two-handed control yoke begins movement down to a certain speed. This speed is usually higher than the speed of the direct bending process, so that movement is happening to a certain point of switching speed, and speed is called free fall. This is also a conditional term, because, in reality, no drop traverses does not happen, because the hydraulic system through the regulation, the rate is fixed in a certain range.

With a hydraulic press brake bending machine design, the operator is in full command of the job. He can meter out just the right amount of fluid to move the ram the exact distance needed. With a CNC sheet metal bender you can easily inch the ram down for scribed line work, and easily locate the stroke bottom for setting up. This gives more accuracy, less operating time, and less training is needed. The hydraulic advantage allows you to instantly stop or start anywhere in the cycle, and allow reversal of stroke direction at any position. Different from a mechanical press brake that can only return the ram to the top after the cycle is complete.

Main Parts of CNC Press bending Machine

Usually, the CNC hydraulic bending machine is the upper piston type press machine, which is composed of the frame, sliding block, hydraulic system, front-loading rack, back gauge, mold, electrical system, foot pedal switch, etc.

● Frame

The frame of the press brake becomes the basis for the installation of hydraulic parts and integrate the oil tank into the stamping frame. The frame of the hydraulic press brake machine is welded by the left and right upright plate, worktable, supporting bodies, and fuel tanks. The worktable is under the left and right uprights. The fuel tank is welded with the uprights, which can improve the rigidity and strength of the frame, as well as increase the heat dissipation area of the hydraulic oil.

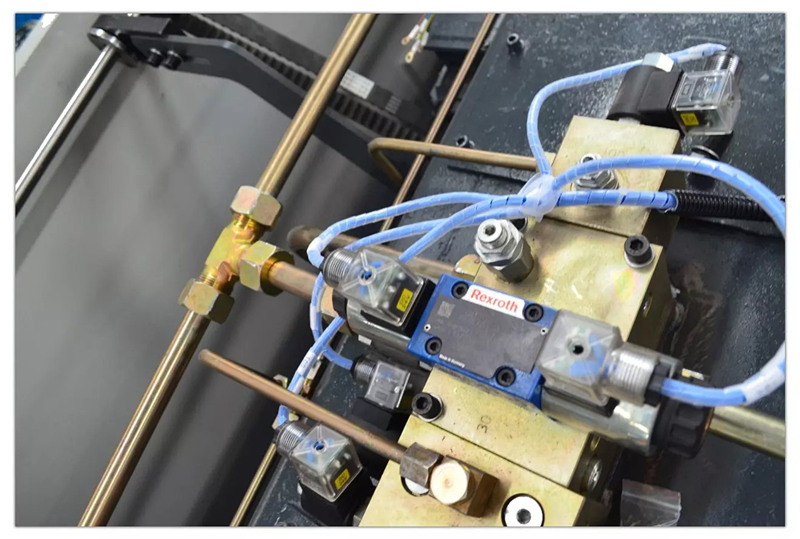

● Hydraulic System

The hydraulic control of CNC hydraulic press brakes requires a high degree of automation and standardization rate in manufacturing. Therefore, the press brakes must integrate the hydraulic system into it. The motor, oil pump, valve are connected with the fuel tank, in order to ensure that the oil tank is filled with oil when the ram is rapidly falling, the structure of the filling valve is adopted, which will not only improve the travel speed of the ram but also save energy.

● Back Gauge

The back gauge of the CNC press brake for sale adopts motor driving transmission, to realize the synchronous movement of two ball screw timing belts. The backgauge distance is controlled by the CNC controller.

● Electrical System

CNC hydraulic press brake machine power supply using three-phase AC 50HZ 380V power, can not only be directly used for the main motor operation, but also for the rear gear servo and equipment lighting use after output AC voltage through the system internal transformer. The other group form into two sets of DC 24V after rectification, one way for CNC controller use, the other for the use of controlling loop.

● Foot Pedal Switch

The pedal switch of the sheet metal press brake is mainly used to control the up and down of the top punch during bending operation. There is also one emergency button on top of the pedal switch for emergencies.

Main Features of Hydraulic Press Brake Machine

- Complete steel-welded structure, with sufficient strength and rigidity.

- Hydraulic down-stroke structure, reliable and smooth.

- Mechanical stop unit, synchronous torque, and high precision.

- Back-gauge distance and upper ram stroke with electric adjustment, and counter display.

- The upper tool with tension compensating mechanism, in order to guarantee high precision of bending.

- X-axis and Y-axis drive automatic control.

The Advantages of CNC Hydraulic Press Brake Machine

● High accuracy of bending

The bending angle error of the hydraulic press bending machine is less than 1 degrees. The main driver of the servo bending machine is driven by the servo motor drive screw. The transmission precision is higher by measuring the bending angle of various specifications plate, the bending angle error can be guaranteed to be within 0.5 degrees.

● Simple Functions

A CNC sheet metal brake is a computer numerically controlled machine where all the required parts can be easily programmed and swiftly manufactured by semi-skilled operators. This is possible as the control guides the operator through a stage-wise procedure. Actually, the simple functions and programming steps of the machine can be learned and practically implemented in the workshop.

● Cost Saving

The CNC hydraulic press brake machine is basically a highly appealing and very sophisticated machine. Moreover, it includes top-grade components, minimizes wastage, and has higher repeatability and traceability. This equipment also helps to save costs in terms of machine setup around 45 percent; material handling around 35 percent; inspection around 35 percent; work in the process around 25 percent; and parts cycle time around 50 percent.

● Simple Design

CNC sheet metal benders have a simple design and easy to operate interface. If you operate it as prescribed and maintain it on a regular base then you can use them for years without any trouble. You would require very few moving parts in a press brake and its maintenance costs are low as well.

The Applications of CNC Sheet Metal Bender

● Automotive panels

● Airframes

● Metal artwork

● Furniture

● Metal containers

● Many other sheet metal forming applications

● Electrical – enclosures

● Machine tool – machine enclosures and doors, coolant, lubrication or hydraulic tanks

● Building and construction – cabinets, ductwork, grilles

● Automotive and aerospace – large panel fabrication