Products Description

Main Features:

1. J21 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

3. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

4. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

Size Information

Specifications | Unit | JH21-25 | JH21-45 | |||

Type | H | S | H | S | ||

Nominal force | KN | 250 | 450 | |||

Nominal Stroke | mm | 3 | 3 | 4 | 4 | |

Slide Stroke | mm | 50 | 80 | 70 | 120 | |

Slide Strokes Per Minute | Fixed | min-1 | 125 | 100 | 95 | 80 |

Variable | 75-150 | 60-120 | 65-115 | 50-95 | ||

Maximum Die Set Height | mm | 265 | 250 | 295 | 270 | |

Die Height Adjustment | mm | 50 | 60 | |||

Between slide center and frame | mm | 210 | 225 | |||

Columns Distance | mm | 450 | 515 | |||

Bottom size of slide | L×R | mm | 360 | 400 | ||

F×B | mm | 250 | 340 | |||

Shank Hole Size | Dia | mm | 40 | 50 | ||

Depth | mm | 50 | 60 | |||

Bolster size | L×R | mm | 720 | 825 | ||

F×B | mm | 400 | 440 | |||

Blanking Hole Diameter | mm | 150 | 150 | |||

Bolster Thickness | mm | 80 | 110 | |||

Bolster Surface Height | mm | 780 | 800 | |||

Overall Dimensions | F×B | mm | 1500 | 1585 | ||

L×R | mm | 945 | 1075 | |||

H | mm | 2120 | 2390 | |||

Distance Between Foundation Bolts | F×B | mm | 980 | 1075 | ||

L×R | mm | 690 | 760 | |||

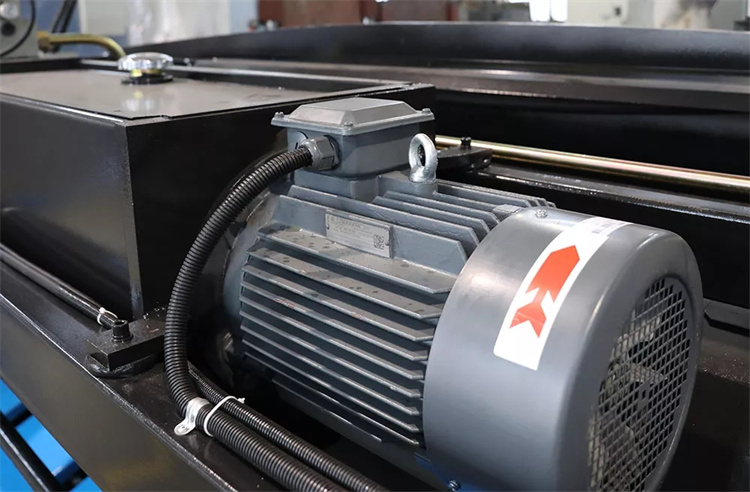

Motor | Power | Kw | 3 | 5.5 | ||

Weight(Approximate) | Kg | 2450 | 3550 | |||

Press Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | |

Machine Details

Standard accessories: Optional accessories:

1) Wet clutch 1) Dry clutch

2) Hydraulic overload protecting pump 2) Pneumatic die cushion apparatus

3) Auto lubrication system 3) Light curtain

4) Manual lubrication system 4) Die quick change device

5) Hydraulic overload protecting pump 5) Foot pedal

6) Joint for miss-feeding 6) Automatic feeding the output shaft

7) Touch screen 7) Speed motor, frequency control

8) Electronic crankshaft angle indicator

9) Cam controller

10) Die height adjusted motor (JH21-100~400)

11) PLC: Programmable logical controller

12) Knock out device

13) Air source quick connector

14)Absorbing pads

15) Working lamp

16) Air blowing

17) Second degree drop

18) Preset counter