Easy and safty control

The control panel includes double hand buttons and emergency stop button and foot pedal control switch is optional.

Manual Slide Adjustment

The press is equipped with a simle and reliable manual slide adjuster with 0.1mm increment indicator.

Mechanical overload protected

A safty block is add inside the slide to protect the die if overload, it is easy to change the safty block by opening window in the side.

1. J23 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

3. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

4. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

Features

1. J23 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

3. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

4. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

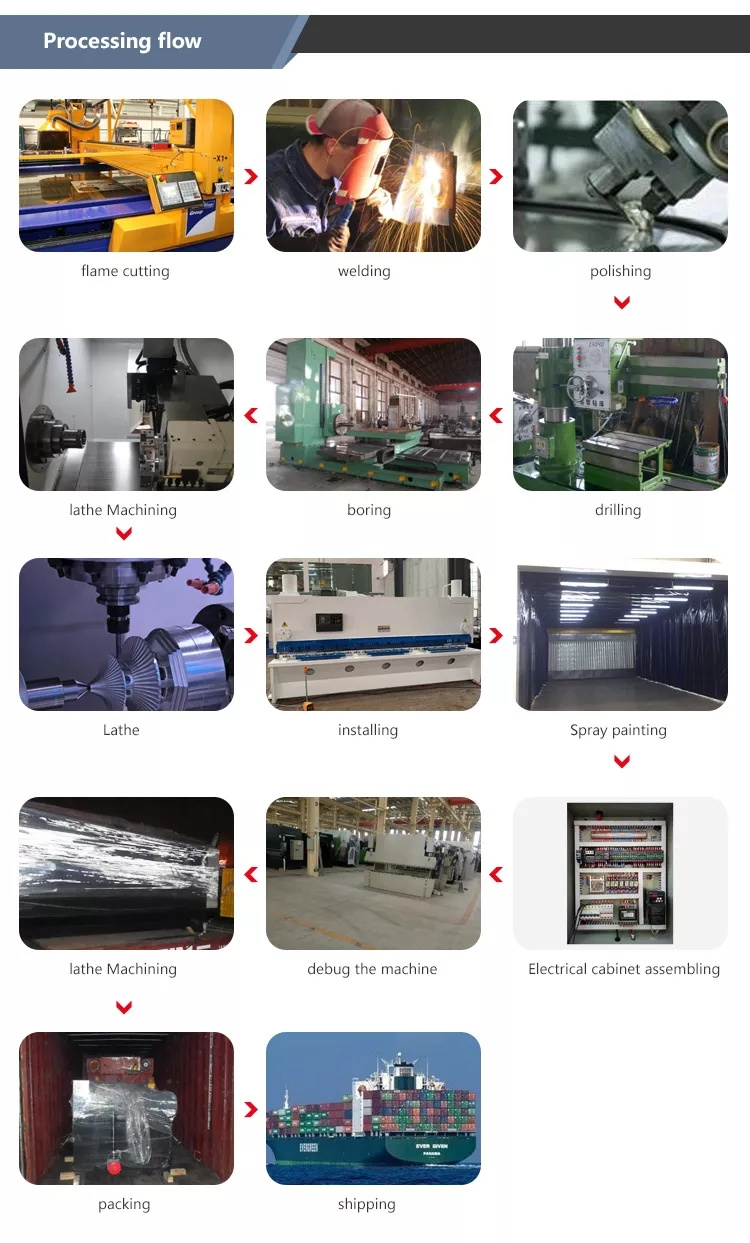

Package