FEATURE

FEATURE

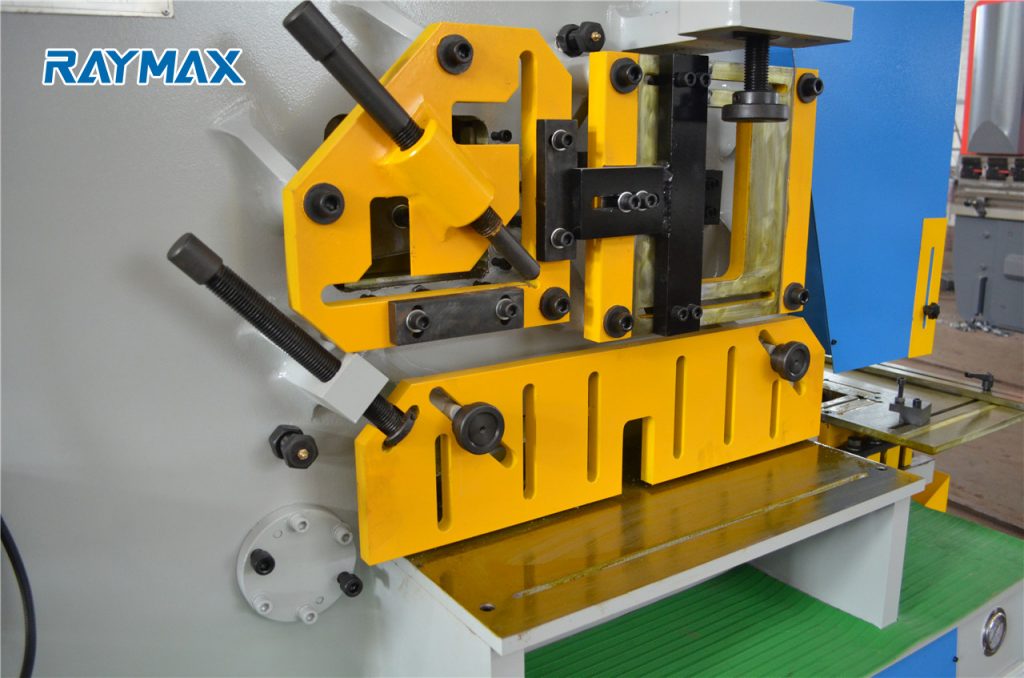

Q35Y series industrial-grade hydraulic ironworker featuring multiple functions, including: round hole, square hole, oblong hole punching; steel plate, flat bar, angle steel, C-channel, H-beam punching; steel plate bending; angle steel shearing, notching and bending; flat, round, square bar, C-channel, I-beam, T-bar shearing/cutting; angle bending and pipe notching. The machine comes standard with: quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more. It's the first choice for metal processing of modern manufacturing industries (such as the metallurgy, bridge, communication, electric power, military and other industries). Our machine is designed via the latest technology and has the virtues of easy operation, low consumption and low maintenance cost. We also can provide customized solutions to better cater for customers' needs. Q35Y series is a quite advanced version compared with standard Q35Y series. Q35Y series have larger power motors and special pumps, so punching position and shearing position can work synchronously.

Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 |

Punching pressure ( T ) | 55 | 75 | 115 | 140 |

Max. cutting thickness (mm) | 16 | 25 | 25 | 30 |

Plate strength (N/ mm2 ) | ≤450 | ≤450 | ≤450 | ≤450 |

Cutting angle (°) | 7° | 8° | 8° | 8° |

Shearing size of one stroke (mm) | 16*250 8*400 | 20*330 10*480 | 25*330 16*600 | 30*335 20*600 |

Slipper stroke (mm) | 80 | 80 | 80 | 80 |

Travel times (T/Min) | 8 | 8 | 8 | 8 |

Throat depth (mm) | 300 | 355 | 400 | 600 |

Punching thickness (mm) | 16 | 20 | 25 | 30 |

Max. punching diameter (mm) | 25 | 30 | 35 | 38 |

Main motor power (kw) | 4 | 5.5 | 7.5 | 11 |

Dimension (L*W*H)(mm) | 1640*730*1770 | 1860*800*1900 | 2350*960*2090 | 2680*1040*2300 |

Weight ( kg) | 1600 | 2000 | 4800 | 6800 |

FEATURE

FEATURE