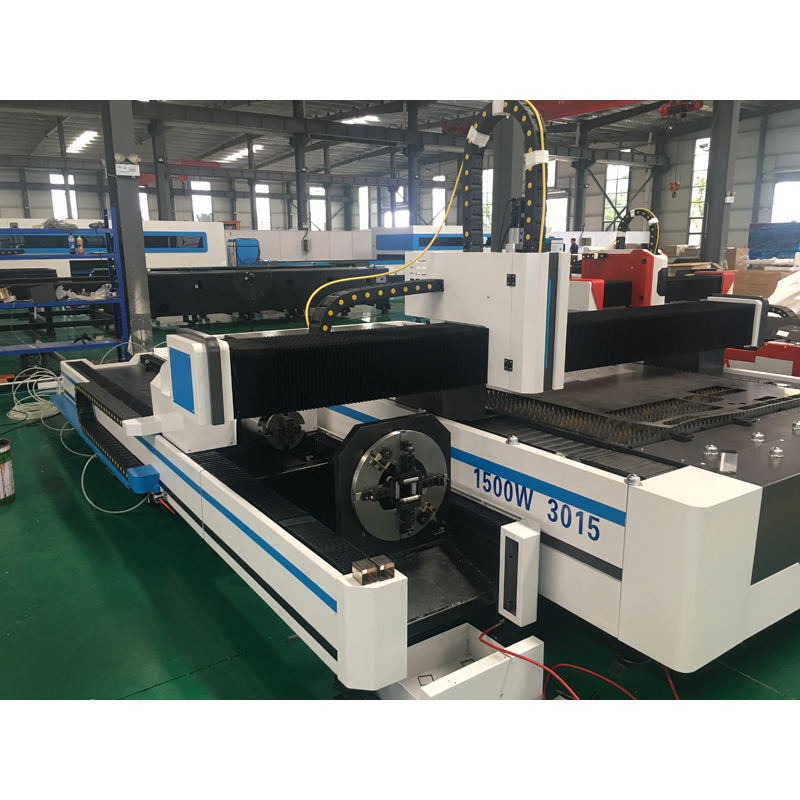

Product Description

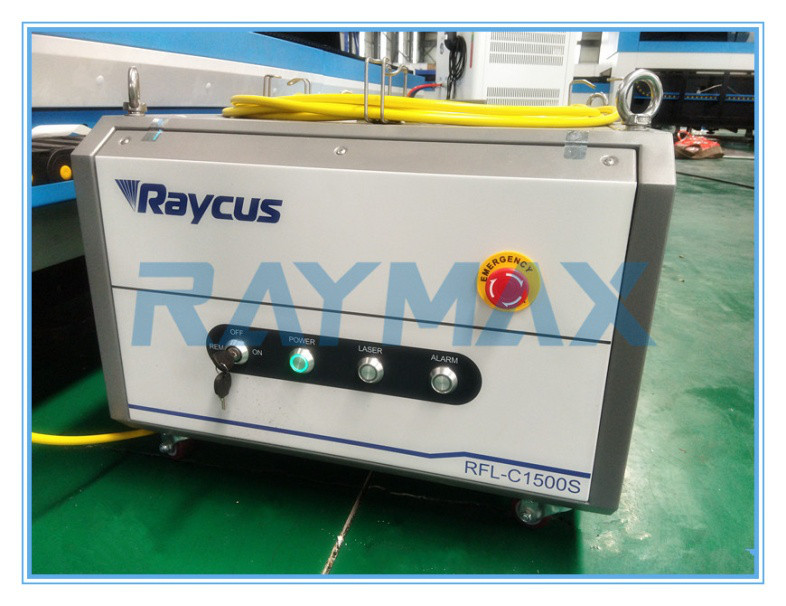

1.Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2. High cutting speed: Cutting speed is more than 20m/min

3. Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100, 000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machinehave three times photoelectric conversion efficiency

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: Fiber line transmission, no need reflect lens, save maintenance cost;

7. Easy operations: Fiber line transmission, no adjustment of optical path;

8. Super flexible optical effects: Compact design, compact and easy to flexible manufacturing requirements.

Details Images

Applicable materials:

Mainly used for cutting carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet metal sheet fast cutting.

Applications:

Applied in medical microelectronics, frames, subway spare parts, machine parts, handicraft, hardware tools, advertising, etc.

Laser cutting software(automatic nesting software) introduction

"Laser cutting design software" is set for flat cutting design software, whose main goal is to provide image processing, parameter settings, the custom cutting process editor, simulation, and idling sorting and processing

It supports the following data input mode

After time support DXF, PLT and other graphical data formats accepted international standard G code

Mater Cam, Type3, Wentai software generated DXF import graphics, text outlines AutoCAD direct extraction system transferred graphic image data, you can edit the layout (like zoom, rotate, align, copy, combination, smooth, merging operation) of the imported data to automatically check the legality, such as: Closed, overlapping, self-intersecting, distance between the detection of graphics, the cutting type (female cut, Yang cut), and external relations, interference relationship, automatic calculation of introducing cutting patterns, export line.

Process according to need, can be freely modified start position and graphics processing direction, while the system dynamically adjust the introduction of lead position, file import always automatically optimize the processing sequence, but also can be manually adjusted to reduce the processing time and improve processing efficiency select the graphic output, support anywhere in the processing of local data, particularly useful for feeding, while you can use the crop function, a graphics processing locally unique breakpoint, the process can go forward along the track, rewind, flexibility encountered each process case, according to the graphic processing, raw material size, automatic nesting