With the continuous development of science and technology, the intelligent numerical control system has led the electro-hydraulic bending machine to a new height. From the most common DA-52S to the upgraded DA-69T system, the Dutch brand DELEM has become the most commonly used high-quality systems of hydraulic bending machine.

Among which DA-52S, DA-53T, DA-58T, DA-66T, and DA-69T have become the main system of our company's electro-hydraulic bending machine because of its convenient operation and powerful functions. So what are the characteristics of each of these five systems, and how to choose?

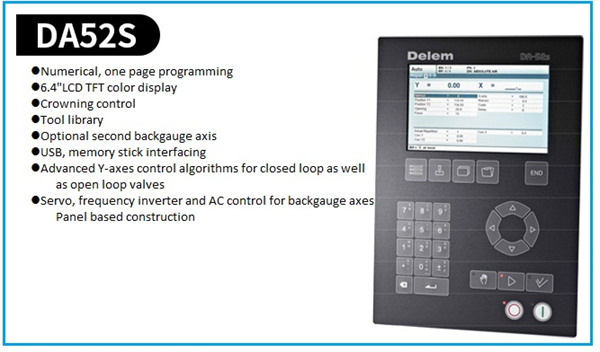

DA-52S control system

The integrated DA-52S numerical control system can not only use torsion axis synchronous bending machine control, but also electro-hydraulic synchronous bending machine control. The panel mounting structure based on 4-axis control can be installed directly on the electric cabinet or in a suspended cabinet.

The DA-52S system with a friendly user interface and TFT true color LCD display possesses all the basic functions of bending machine control. Its unique "shortcut key" method provides fast and concise programming. Y-axis angle programming, workbench deflection compensation function, and pressure control are all standard configurations. The DA-52S system provides a stable and reliable solution. The equipped USB interface greatly facilitates the quick backup of products and molds.

DA-52S is an important transition for DELEM to develop from torsion axis bending machine CNC system to electro-hydraulic bending machine CNC system. DA-50Touch series bending machine system provides a multi-functional solution for powerful electro-hydraulic bending machines. Of course, DA-52S may not be powerful enough compared to the subsequent DA-53T or even DA-69T, but considering the price, DA-52S is very suitable for users with no high requirement.

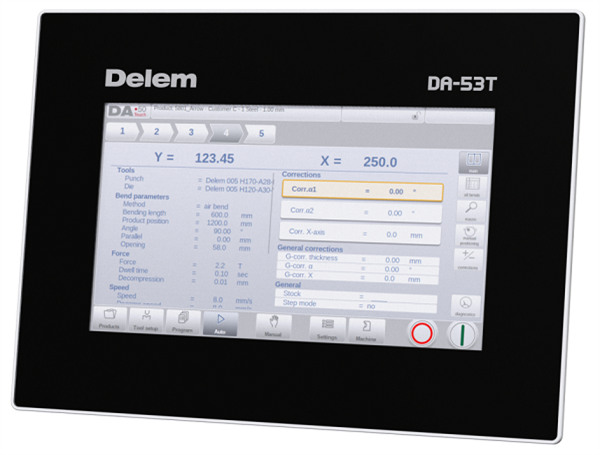

DA-53T control system

The brand-new DA-53T is a new member of this series, providing a perfect full-touch control solution for electro-hydraulic bending machines. The panel type is the basic installation method, which can control up to 4 axes, and the suspended installation method can be selected.

It is equipped with a 10.1" high-resolution TFT color wide-body display, integrated with an industrial-grade multi-touch screen, allowing easy access to the Delem user interface. You can use shortcut keys to quickly switch between programming and processing interfaces. And the overall design is based on ergonomics which is optimized to make the operation more convenient and user-friendly.

Through the quick and convenient "programming directly to production" process, greatly reducing the time of machine tool adjustment and trial folding. The USB interface facilitates quick backup/restoration of molds and products. Standard Configuration 3+1 (Y1, Y2, X-axis, and deflection compensation), and another optional axis can be used for the R axis or Z axis.

DA-53T Main features

- "Hot-key” touch navigation

- 10.1" high-resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

DA-53T Technical data

| Standard | |

| Display | Colour LCD display |

| Type | 10.1" TFT, high brightness |

| Resolution | 1024 x 600 pixels, 32 bit colour |

| Touch sensor | Full touch screen control (PCT-touch) |

| Backlight | LED |

| Storage capacity | 1 GB |

| Product and tools memory | 256MB |

| Exchangeable memory | USB flash memory drive |

| Offline software | Profile-53TL |

Compared with the DA-52S system, the DA-53T retains the advantages of compensation system control, USB backup and recovery, and 24 languages available. It enlarges the screen to 10.1" and makes the screen touchable. Screen, and supports offline software use, which makes it more convenient and smooth for users to use, but the price has also increased accordingly.

DA-58T control system

DA-58T represents the new level of development of a complete 2D graphics control solution for electro-hydraulic synchronous bending machines.

15" high-precision color TFT display, integrated industrial-grade multi-touch technology, can easily access the user application program interface of ELEM. It provides more direct quick navigation function keys for product programming and machine setting, shortening the operation time. Through fast and convenient programming to the production process, the time of machine tool adjustment and test bending is reduced to a minimum.

Independent CNC programming interface, all axes automatically calculate the position, real proportional machine tool, and mold simulation bending process. DA-58T provides 2D programming that includes automatic calculation and collision detection of the bending process. The production model of DA-58T provides the simulation of the bending process of the product to help the operator operate in the processing. The standard machine tool functions Y1-Y2 and X-axis, the second two gauge shafts can be used for R-axis or Z-axis, and the compensation shaft is also standard configuration.

DA-58T Main features

- 2D graphical touch screen programming

- 15" high-resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

DA-58T Technical data

| Standard | |

| Display | Colour LCD display |

| Type | 15" TFT, high brightness |

| Resolution | 1024 x 768 pixels, 32 bit colour |

| Touch sensor | Full touch screen control (PCT-touch) |

| Backlight | LED |

| Storage capacity | 1 GB |

| Product and tools memory | 256MB |

| Exchangeable memory | USB flash memory drive |

| Offline software | Profile-58TL |

Compared with DA-53T, DA-58T has enlarged the screen to 15". It also adds functions such as drawing and 2D graphics programming. It also adds a network interface that can be directly connected to the Internet and a computer universal option, allowing bending of the workpiece to become smarter.

DA-66T control system

A new generation of touch-sensitive numerical control systems, DA-66T, provides more efficient programming, operation, and control for today's bending machines. Combined with modern advanced technology, the operation is more convenient and productivity is improved. The user application program interface operated by the infrared touch screen provides more direct quick navigation function keys for product programming and machine tool settings, reducing operation time.

DA-66T provides 2D product programming, automatic calculation of bending procedures, and collision detection functions. 3D Omni-directional, multi-station molds show the feasibility of bending operations of real machine tools in real-time. It uses more efficient algorithms to optimize the work of the entire machine tool, shorten the operating cycle, improve the efficiency of the machine tool. And at the same time, it is more convenient to adjust and control the machine tool. At the top of the screen is the OEM panel for OEM factory machine functions and application switches. OEM panels can be individually designed as required.

DA-66T Advantages

The new generation DA-Touch controls offer an even higher grade of efficiency in programming, operation, and control of today’s CNC sheet metal press brakes. Ease of use combined with state-of-the-art technology goes hand in hand, improving productivity.

The touch screen gives access to the proven Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimized ergonomics throughout the application.

The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimize the machine cycle and minimize set-up time. This makes using press brakes easier, more efficient, and more versatile than ever.

DA-66T Technical data

| Standard | |

| Display | Colour LCD display |

| Type | 17" TFT, high brightness |

| Resolution | 1280 x 1024 pixels, 16 bit colour |

| Touch sensor | Full touch screen control (IR-touch) |

| Backlight | LED |

| Memory capacity | 1 GB |

| Product and tools memory | 256MB |

| Characteristics | 3D graphics acceleration |

| Networking | Standard Windows® networking |

| Safety system | Emergency switch |

| OEM machine functions | Integrated OEM-panel |

| Exchangeable memory | USB flash memory drive |

| Offline software | Profile-TL |

Each DELEM controller system has its own features and advantages. RAYMAX's CNC sheet metal bender has equipped different CNC control system which can meet your various needs. Contact us to know more!