Characteristics

1. Gantry double drive structure, smooth and reliable movement;

2. Independent research and development design, the manufacture of machine tool bed, special processing technology, machine tool precision, stable and reliable, long life;

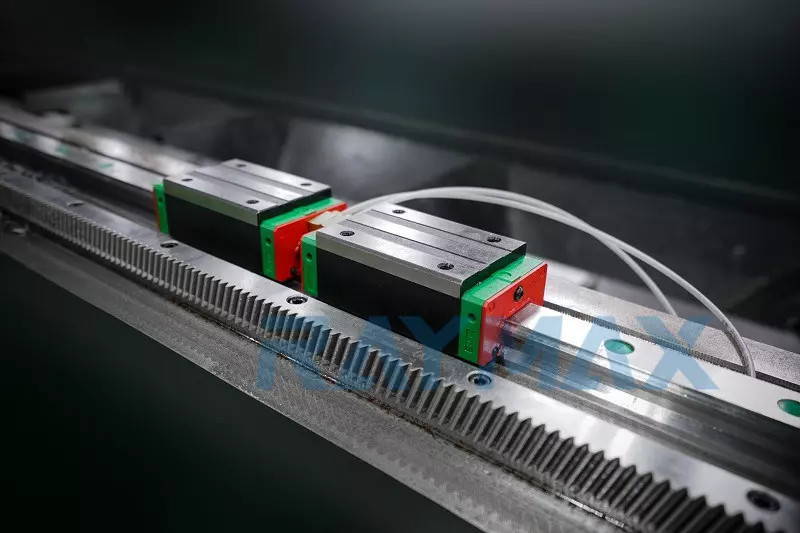

3. Precision gear rack drive, with high response and high precision servo motor;

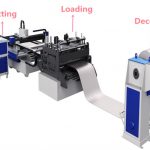

4. Scroll working table is more efficient for material sheet loading and unloading ,and increases the production safety.

5. High precision laser cutting head, imported optical lenses, is focused on the fine, the adjustment is convenient, cutting perfect;

6. A double closed-loop control capacitive height controller, low requirement to the steel sheet, cutting quality is stable and reliable;

7. CNC system is concise and easy operation, low requirements for the operator;

8. Cutting graphic input multiple formats, powerful draw and edit graphics function;

9. Special cutting software, cutting technology experts, data call functions;

10. Scroll working table is more efficient for material sheet loading and unloading ,and increases the production safety.

11. Better beam quality: smaller focused spot, finer cutting lines, smooth cut, beautiful appearance, no distortion, higher work efficiency, and better processing quality.

12. It adopts professional software to realize the timely processing of various graphics and characters, and is simple and convenient to use.

13. Energy saving and environmental protection, perfect smoke and dust removal system.

Technical parameter

| Max cutting speed | 90m/min |

| Max Acceleration | 1.0G |

| X/Y positioning accuracy | 0.05mm/m |

| X/Y Repeated positioning accuracy | ±0.03册 |

| Operating voltage | 380V/50HZ |

| Laser power | 1KW -6KW |

| Machine tool power | 6KW |

| Machine running temperature | 0℃-40 ℃ |

| Machine running humidity | <90% |

| Transmission | Precise rack and pinion |

Applicable materials

Specially used for cutting 0.3mm -25mm carbon steel ,0.5-12mm stainless steel ,galvanized steel, electrolytic zinc-coated steel, silicon steel,0.5mm-6mm brass and red copper and other kinds of thin metal sheets .

Detail

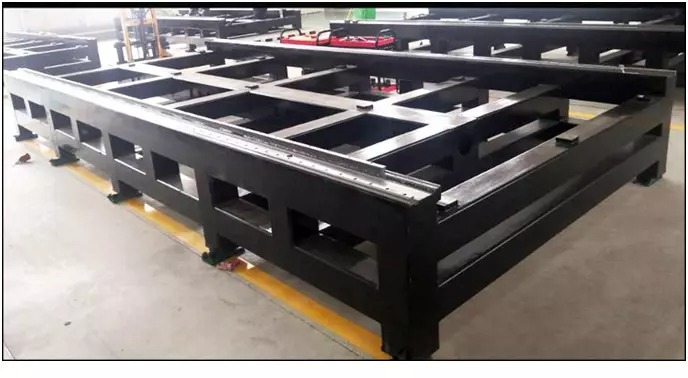

1. Steel lathe bed, 2 tempering process

2. The structure adopts industrial heavy steel structure ,under heat treatment, suffer lower temperature tempering and annealing ,won't deform after long time use.

3. Flake graphite cast iron with a minimum tensile strength of 200 MPa.

The beam adopts the fourth-generation extruded aviation aluminum forming manufacturing process, and is extruded with a 4300T press. The hardness can reach T6 after aging treatment. Its honeycomb structure design has light weight, high strength, high temperature resistance and corrosion resistance, which greatly increases the processing speed.

RGH-CA linear guide, high rigidity, high load bearing ,under the same load requirements, compared with ball screw linear guide has smaller volume, can bear high torque capacity

Fiber laser cutting head

1. Maximum air pressure 25 BAR

2. Focus lens preset function

3. Standard focal length options are 5.0", 7.5" and 10" inches

4. Easy to check and replace various interfaces

5. Quickly replace and check lenses with chuck type frames

6. Equipped with electronic anti-collision signal

7. Lens water cooling system

8. The cutting head adopts magnetic anti-collision hanging mounting

9, the lens and nozzle blowing air cooling

10. System maintenance and operation are very convenient

11. The lens holder can be adjusted electrically or manually, up to ±9.5mm

Scroll working table is more efficient for material sheet loading and unloading ,and increased the production safety

Fiber laser cutting machine with Scroll working table can be combined with an automatic production line with a coiler and a leveler, which greatly improves production efficiency.

1.Energy saving and environmental protection, perfect smoke and dust removal system.

2.The operating cost is low, meeting the needs of 24-hour industrial production.

| Style | 1530 | 2040 | 2060 |

| Processing wide (mm) | 1500x3000 | 2000x4000 | 2000x6000 |

| The workbench exchange way | Translation exchange up and down | ||

| Overall dimensions (mm) | 8700*4050*1700 | 10800*4550*1750 | 15100*4550*1800 |