Guillotine Shearing Machine

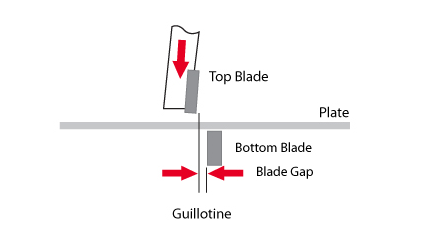

A hydraulic guillotine shearing machine is ideal for custom metal fabrication applications. The major components of guillotine sheet metal shears, both over-crank and under-crank, including the side-stands, the bottom connecting plate, the hold-down, the top connecting plate, and the blade carrier. Its worked cutting device that comprises a horizontally oriented fixed lower blade and a horizontally-oriented moving upper blade that goes in vertical guide channels. It accompanies the ability to cut the most demanding materials precisely and productively. A hydraulic guillotine shear can be utilized thickness up to cut mild steel with thickness up to 6.35 mm and stainless steel with thickness up to 3 mm. The guillotine shearing machine is designed with the most extreme cutting length of 4000 mm. Shearing machine is one of the forging industrial machinery and intends to cutting hard iron sheets and metal bars by applying a high-pressure device on rotational cutting edges. The shearing machine has a moving upper blade and a fixed lower blade and shears a sheet by reciprocating linear motion with one blade relative to the other. Moreover, it applies a shearing force to the metal sheets of various thicknesses with a reasonable blade gap to break the sheets in the required size.

Hydraulic guillotine is suitable for making heavy-duty cutting off for more production requisite. The hydraulic guillotine shearing machine is known for its great efficiency in shearing. It is designed as a guillotine with a table to store the sheared material. The actuator is formed by an electric motor in conjunction with a gear mechanism that directly drives the shearing beam. When cutting, the locking system is designed to avoid damaging the metal sheet. When the guillotine sheet metal shear is in operation, Its rigidity, strength, vibration characteristics, dynamic stresses, and factor of safety need to be examined critically. The vibration and strength characteristics of the machines and the blade carrier, when the thickness of the plates are changed, also need to be examined.

As a top 10 guillotine shearing machine manufacturer, RAYMAX’s hydraulic guillotine shears have strong welded steel construction suitable for long operation time. The design of the frame, cutting beam, and back gauge to ensure the highest rigidity and resistance to torsions and deformations. With a strong design, customers can get maximum cutting quality. With Easy to use CNC controller operator enters the thickness and the type of the material and controller automatically adjust the cutting angle and blade gap. Moreover, our hydraulic guillotine provides the wealth of standard and special equipment which allows delivering the optimal machine for specific applications with the possibility of replenishment during its use.

The hydraulic guillotine shearing machine is suitable for working over sheet metals and plate metals. They are intended for cutting various types of table sheet materials made of steel, stainless steel, aluminum, copper, cardboard and etc. The guillotine shear is featured with excellent functional aspects that make it a top preference in many metalworking industries. RAYMAX, a professional guillotine shearing machine manufacturer in China, provides high productive hydraulic guillotine shearing machine with rock-solid hydraulic, accurate ball screw back gauge, user-friendly CNC Controller.

Guillotine Shearing Machine Principle

Advantages of Hydraulic Guillotine Shearing Machine

● Precise Cuts

The hydraulic guillotine shear makes clean, straight-line cuts on flat sheet stock. It is a much straighter edge than torch cutting since it cuts without forming chips or burning the material, unlike traditional torch cutting. This allows your manufacturing or production facility to make products that are as precise as possible.

● Compatibility

The hydraulic guillotine shearing machine is compatible with working along with an advanced integrated hydraulic system where reliable results can be achieved with ease. Its compatibility also works in adopting a welding structure made of steel plate and vibration and thus leaves space for no stress at all.

● Minimal Waste

Perhaps the biggest advantage of guillotine sheet metal shear is that it produces minimal to no waste. Unlike other methods of cutting, shearing has virtually no loss of material. Since the machinery can cut relatively small lengths of material at a time, and the shearing blades can be mounted at an angle, shearing also uses less force per project than other methods.

● Safety

Another advantage of using a hydraulic guillotine is that they can be very safe to use compared to other types of cutting machines. Unlike torch cutting or other methods, the operator stands clear of the machinery and does not risk burns. As long as the proper safety precautions are taken, and the machine receives regular maintenance and upkeep, shearing can provide clean lines with minimal risk.

Caution of Guillotine Shear

(1) Check the machine before even turning it on. This includes examining all parts to make certain they are in good working condition with the appropriate amount of lubrication, screws tightened in place and sharp blades. Additionally, check gas levels and the working pressure. This should not exceed 90%of the rated pressure equipment.

(2) Check the gap between the blade frequently and adjust the gap according to the thickness of different materials.

(3) The blade must be kept sharp, and the cut surface is not allowed to have a scar, gas cut seam, and protruding burr.

(4) If the machine stops functioning, ensure the power supply is turned completely off. Then, check your lubricating oil levels and try cleaning the hydraulic cutter. If this does not remedy the problem, find the guillotine shearing machine’s user manual for further insight into the problem. Do not begin to operate the guillotine shearing machine again until you are absolutely certain it is in perfect working order.

(5) When adjusting the machine, it must be stopped to avoid personal and machine accidents.

(6) Ensure you have the right size blades for the material you are using. Do not cut strips to avoid damage to the machine. The cutting size of the most narrow sheet shall not be less than 40mm. Before feeding any material through the blades, check the placement of your fingers and hands to ensure they are not in harm’s way.

(7) If found abnormal noise or oil tank overheating phenomenon during operation, should immediately stop the shearing machine to check, the highest temperature of oil tank cannot exceed 60 °C.

Applications of Guillotine Shearing Machine

The hydraulic guillotine shearing machine is widely used in aviation, light industry, metallurgy, chemical, construction, shipbuilding, automobile, electric power, electrical appliances, decoration industries. As a top10 guillotine shearing machine manufacturer, RAYMAX’s hydraulic guillotines are widely accepted around the world in various industries that are involved in the production of Shipyard, Construction Machinery, Boiler, Aviation, Steel and Aluminum Fabrication, Aerospace, and others.