Shearing machines are often used in the sheet metal processing industry. The seemingly simple shearing action actually contains many tricks, from the adjustment steps of the blade gap to the adjustment techniques for different materials, and even the selection of blades. Related to the cutting quality, the following will introduce the relevant content of the shearing blade gap adjustment in detail from many aspects.

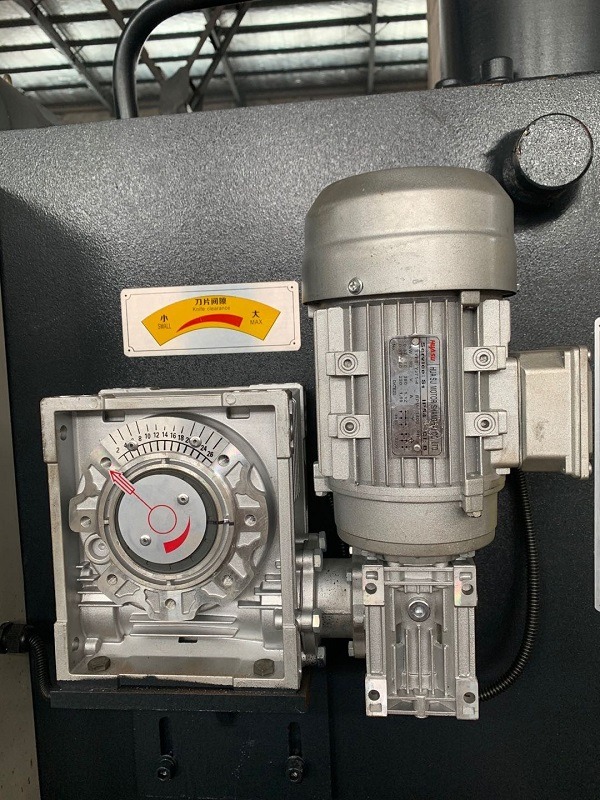

The blade gap adjustment hand wheel: (hydraulic swing beam shearing machine)

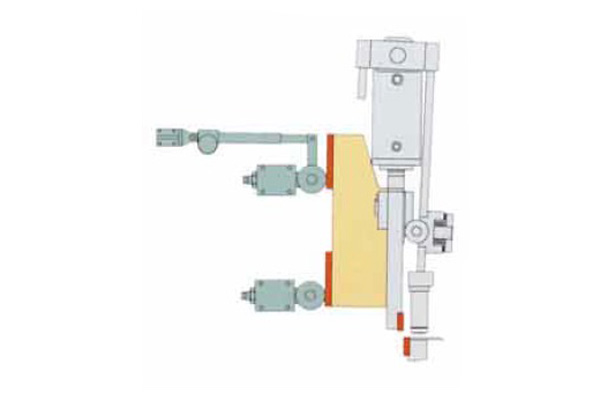

Electric adjustment of blade edge clearance (hydraulic guillotine shearing machine)

Blade clearance of different shears

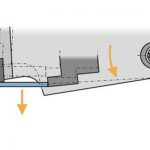

The swing beam shearing machine is equipped with a fast blade gap adjustment mechanism, which can adjust the blade gap that is good for cutting according to different plate thickness and materials, and is equipped with an accurate parameter table for reference selection, and obtains satisfactory cutting quality through reasonable blade gap. As the tool post rotates, the shearing angle and shearing gap of the swing beam shears will change.

Adopt three-points rollers guide, through the force to the front roller by the papilionaceous spring, the cutting beam keeps in touch tightly with the two back rollers. When cutting, the system will electrically adjust the knife edge gap according to the needs of different sheets to obtain better cutting quality.

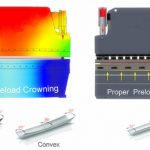

The difference in blade gap adjustment

The swing beam shearing machine have the function of manually adjusting the blade gap, just turn the handle. The guillotine shears have the function of electrically adjusting the blade gap, which can be adjusted more conveniently and accurately through the system, which is beneficial to obtain better shear quality.

| Blade gap adjustment steps |

| 1. Remove the lower blade and clean it piece by piece |

| 2. The blade can be used on all four sides, and the selected one side is tightly installed. And check the straightness of the blade in the horizontal and vertical directions. |

| 3. The upper blade is fixed and cannot be adjusted. We adjust the shear blade gap by adjusting the lower blade. |

| 4. Find the left and right screws of the lower blade to increase the clearance, generally on the outermost side. |

| 5. Find the two set screws on the left and right of the lower blade that push the lower blade to narrow the gap. There are locked backup nuts on them. Generally, on the inside. |

| 6. Loosen the left and right four bolts of the lower blade table |

| 7. The upper blade is lowered to the proper position by manual turning, and the operator goes to the blanking area of the shearing machine to start adjustment |

| 8. Use a feeler gauge to roughly adjust to 0.5 mm from the unoccupied part of the upper and lower blades of the left hand |

| 9. Manual turning makes the blade move up to the middle position and roughly adjust to 0.5 mm. |

| 10. Manual turning makes the blade move up to the right position where the upper and lower knives are not disengaged. The middle position is roughly adjusted to 0.5 mm. |

| 11. Manually turn the upper blade to the proper position and start fine adjustment. |

| 12. Use the feeler gauge to fine-tune the position where the upper and lower blades of the left hand do not bite until the three wires of the feeler gauge can enter the five wires. |

| 13. Manually turn the blade up to the middle position and start fine adjustment until the feeler gauge can enter three wires and five wires cannot enter. |

| 14. Manually turn the blade up to the position where the upper and lower knives are not disengaged on the right side and start fine adjustment until the feeler gauge can enter three wires and five wires cannot enter. |

| 15. When the cutting edge of the shearing machine is sharp, if there are burrs on the edge of the cut sheet, the gap between the upper and lower blades can be appropriately reduced. |

Common problems and knife adjustment skills

The most frequently encountered metal plates are:

1. Thick plates over 13mm.

2. 0.2~4mm thin plate.

3. Flower board.

4. High tension plate (usually used in automobile sheet metal).

5. Titanium plate

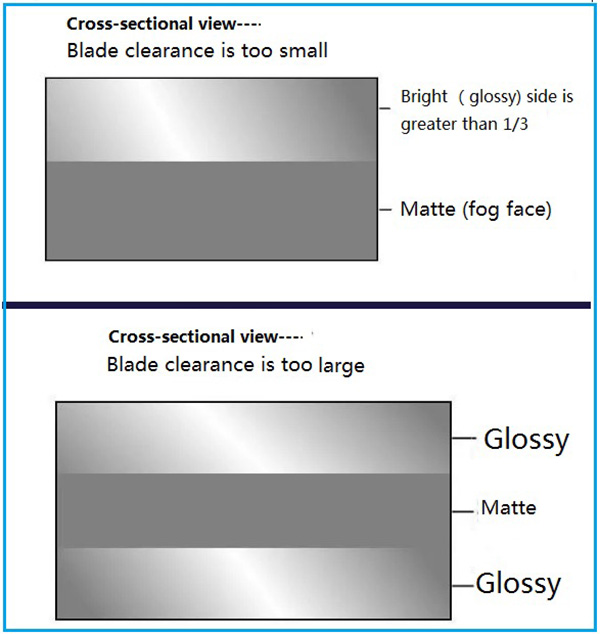

The most common blade problem is chipping or tool dent. In response to these problems, we must first determine the gap between the upper and lower blades.

The adjustment skills of blades

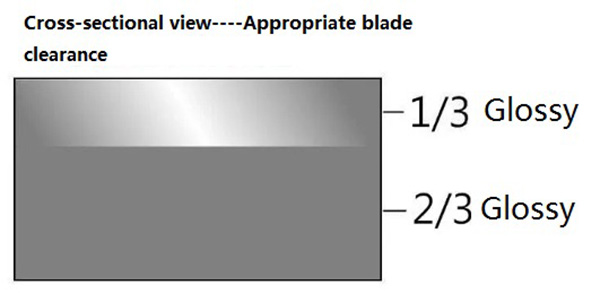

When adjusting the blade, you should set the gap from about 2~3mm thicker than the thickness of the plate. That is to say, when you want to cut a 5mm thick plate, you should start adjusting from 7mm or 8mm, and slowly adjust it down, when you cut it out The cutting surface of the plate shows 1/3 bright surface and 2/3 matte surface, which achieves the best cutting effect. The details are as follows:

The gap setting when cutting the pattern board is tricky, and it must be adjusted from the thickest thickness calculated from the most convex point of the pattern board, instead of using the board thickness directly. Also, cutting the convex side of the pattern face down can extend the life of the tool.

In addition, the material of the plate must be considered, especially when cutting stainless steel. The cutting tool must be sharp, wear-resistant and tough. Therefore, the blade of the hydraulic shearing machine should be discussed. In addition to the angle of the knife edge and other appearance design and production precision, the selected material is a key factor affecting the quality of the tool.