Feature

● The whole machine is in sheet plate welded structure, entire welded frame ,with internal stress eliminated by vibration aging technology, high strength and good rigidity of machine

● Double hydraulic oil cylinder is applied for upper transmission, provided with mechanical limit stopper and synchronous torsion bar, typical of stable and reliable operation, as well as high precision

● Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of gliding block ,and fitted with digital display device ,easy and quick in use

● Slider stroke adjusting device and back gauge device: electric quick adjusting ,manual micro adjusting ,digital display ,easy and quick in use

● With a 180-degree swivel boom, it is easy to use and debug, and is installed to suit the height of the human body.

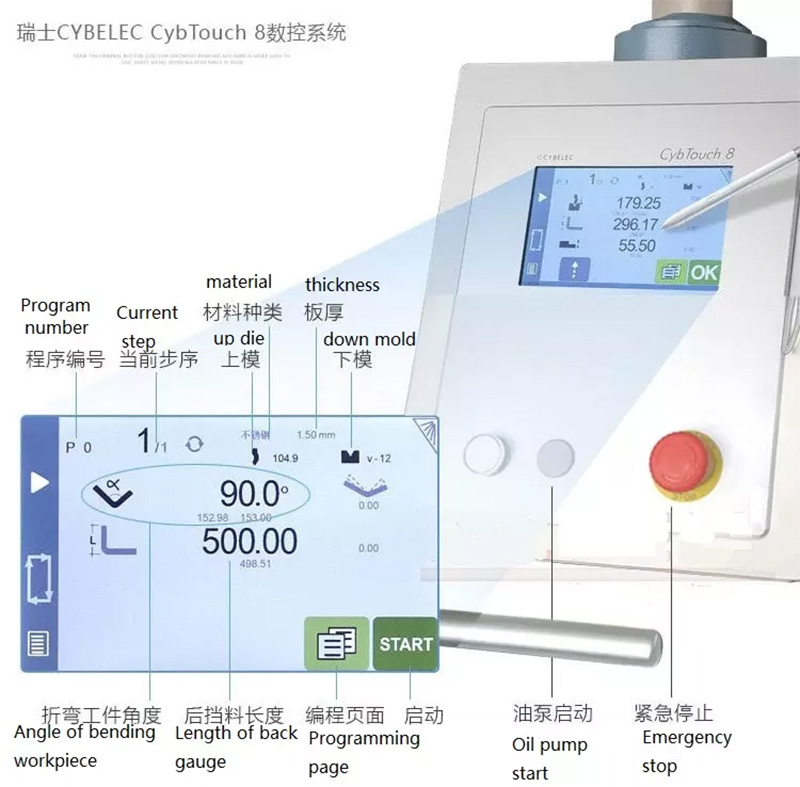

● Using CT8 CNC system, touch screen operation, direct and efficient.

● With angle programming function, zero-based experience can also be operated.

● Equipped with a quick clamping of the mold to quickly change the mold.

● Electro-hydraulic synchronous proportional valve control accuracy, bending accuracy is higher.

● Double-axis rear material structure, high-strength channel steel material, strong high-precision zero clearance.

● Adopt the domestic first-class brand of oil cylinders, and use imported German hydraulic valve sets, the quality is guaranteed.

● Using the hydraulic deflection compensation mechanism, the system automatically compensates and automatically corrects the bending angle.

● The speed of the slider is up to 200mm/s, the mechanic is perfectly debugged and the noise is low.

CNC press brake frame

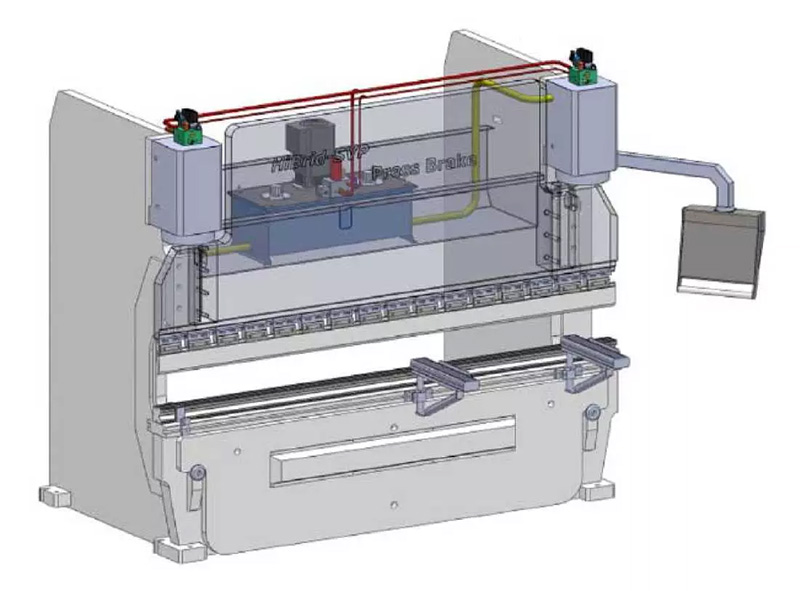

The cylinder is forged as a whole, and the piston rod is chrome-plated three times and mirror-finished, which effectively provides wear resistance and precision, and the structure is simple and stable.

1. Use Japanese NOK complete sets of seals to reduce the risk of oil leakage.

2. The use of hybrid servo technology not only saves energy, but also improves response speed.

3. The original Qingyuan roller type four-point guide rail technology, compared with other similar products, will not cause the guide rail detachment phenomenon, greatly improving the safety, stability and processing accuracy of the machine, compared to the same level The service life of rack drive technology is increased by at least five times.

Machine introduction

● Integrated steel sheet welder structure ,eliminate stress by vibration, with good rigidity and stability

● The mold is processed after casting, with high precision and good strength .

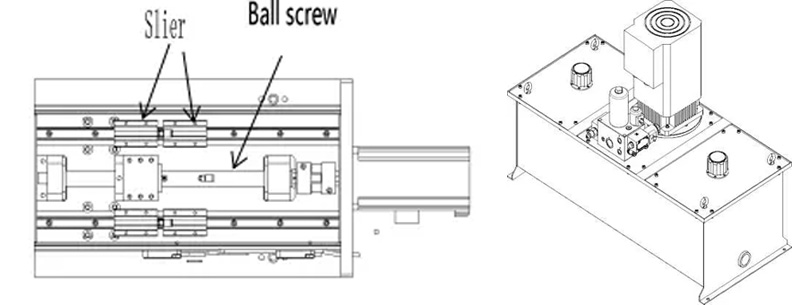

● Screw drive, high precision, double sliders, good stability .

● In order to ensure the accuracy and stability of the machine during operation, the backgauge adopts a screw drive method to ensure the accuracy during operation. At the same time, double guide rails are used to ensure more stable operation of the machine and minimize run out

● Compact design, more convenient installation. Use stainless steel oil tank, easy to disassemble and assemble oil pump .

● Adopt SVP servo pump system, servo motor drives fixed displacement oil pump. In addition to the hydraulic power transmission that converts the mechanical energy into the kinetic energy of the hydraulic medium, the system also has the speed of the oil cylinder controlled by the size of the pump and the speed of the servo motor. With the help of displacement sensors, the speed and position of the cylinder piston can be precisely controlled according to the required work cycle timing chart .

● Finite element analysis to get the best rigidity and weight .

● The entire machine is designed with software for finite element analysis and strict stress detection to ensure that the machine meets the load requirements during operation, while the structure is more refined and the design is more reasonable.

Can respond quickly to all materials of plates

There is no need to set the processing conditions every time, and the bending processing parameters, bending pressure, compensation amount, etc. can be automatically determined. During the processing, the bending processing parameters can be simply edited and changed. The changed data can be immediately reflected in the actual processing. These data can be stored, and the CNC system will continue to evolve.

The best partner for sheet bending, Swiss Cybtouch bending software

The system is powerful and easy to use. Through simple debugging, it can precisely match the needs of the bending machine it controls. CybTouch has a very user-friendly touch screen interface. So CybTouch is a practical and intelligent CNC system, easy to learn and use for many end users .