Feature

1. Machine body adopts integrated welded structure. The main parts of the machine was analyzed by ANSYS finite element analysis software, which ensures the reliability of the machine and the precision of the entire machine; Backgauge is driven by digital AC servo motor, moved with ball screw, guided by linear guide .

2. The main oil cylinders fitted on both sides adopt closed loop control mode which is composed of Germany electro-hydraulic servo valve and imported grating ruler, breaking through the stroke control mode of traditional mechanical stop bending machines, ensuring the high precision of the glide position, the accurate and stable operation, the high precision of bending, and high precision of the repeated positioning of slider;

3. The functional components of the back gauge are all imported, ensuring the stopping precision. The cnc hydraulic press brake bending machine also can adopt more functional multi-axis blocking according to the customers' requirements;

4. The hydraulic system adopts integrated control system imported from Germany, which decreases the installation of pipelines and ensures working stability of the machine too! and conciseness and beauty in appearance;

5. C-shaped plates are fitted on both sides of the machine body, and the high precision grating ruler is fitted on the C-shaped plate. Thus to avoid the influences on bending precision arising from distortion of machine body during bending process;

6. The lower workbench is fitted with hydraulic automatic deflection compen- sation mechanism, ensuring effective compensation without blind area and high precision of bending, so that long stability is guaranteed.

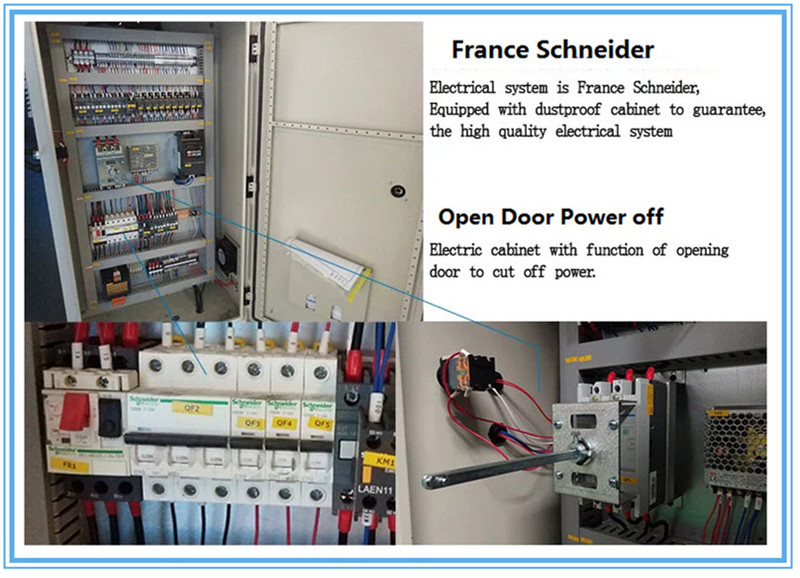

7. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety

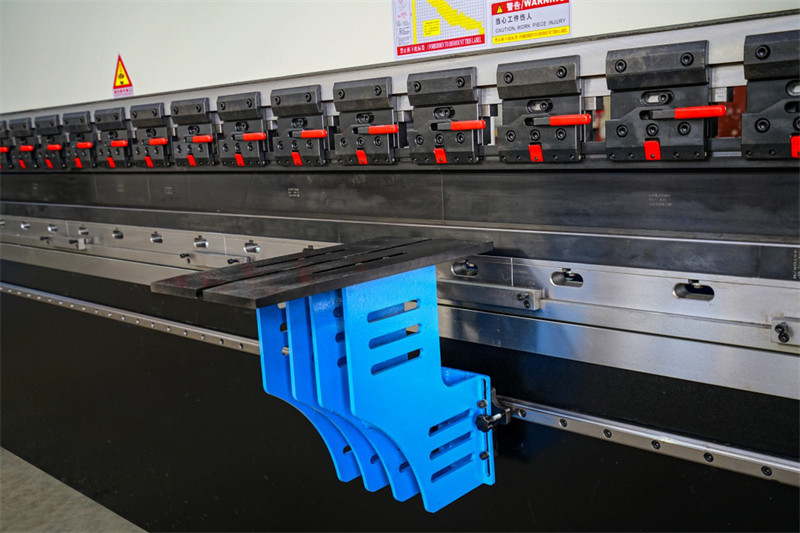

Quick clamp

1. The mold can be installed and removed to the left and right when pull the red handle

2. The mold can be installed up and down when press the button

3. scale more accuracy

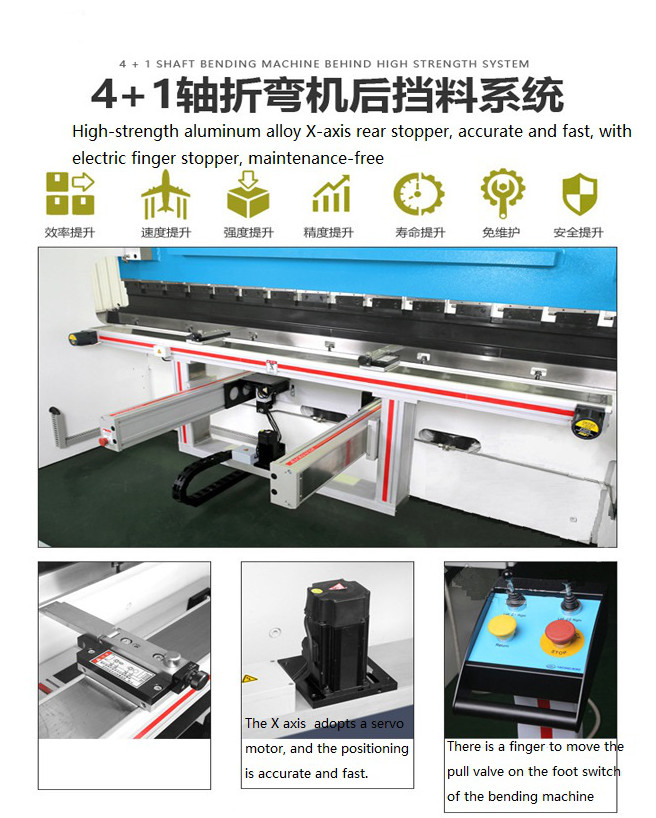

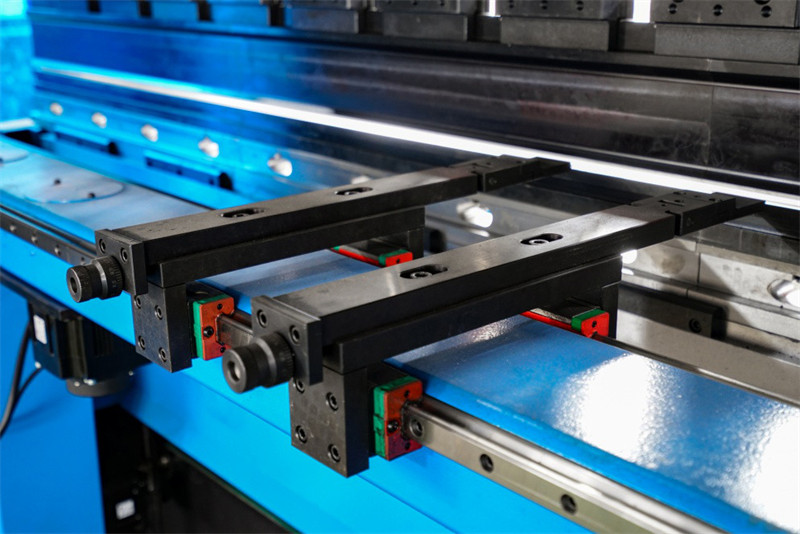

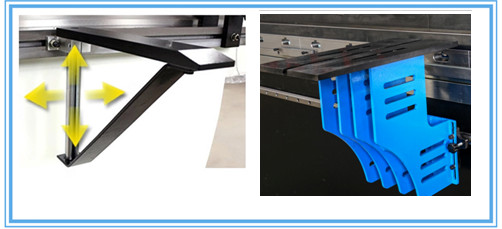

Novel and unique dual linear guide rail structure to ensure excellent positioning accuracy

Double structure front arm is higher rigidity ,superior carrying capacity .It can be adjusted up and down or move along the workbench from side to side and improve work efficiency

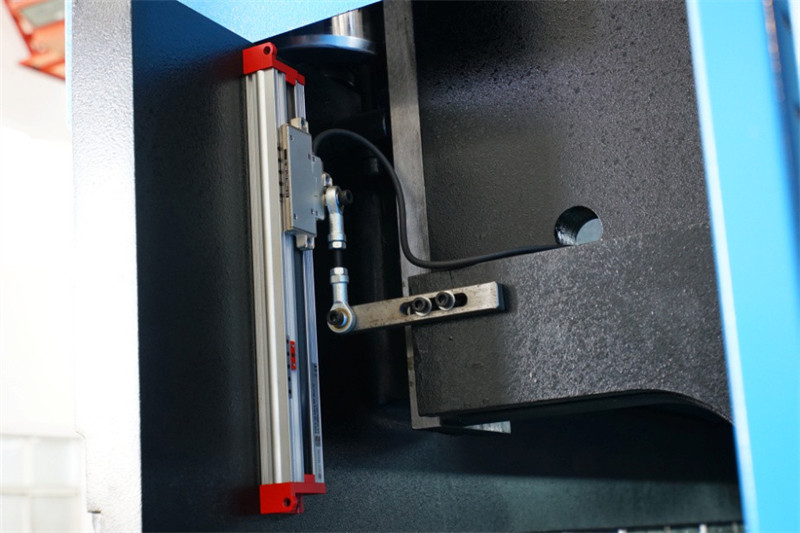

1. High-precision grating ruler and cylinder inlet proportional valve match control angel.

2. Measuring step 5 um connectiong rod connection

3. Large mounting tolerances

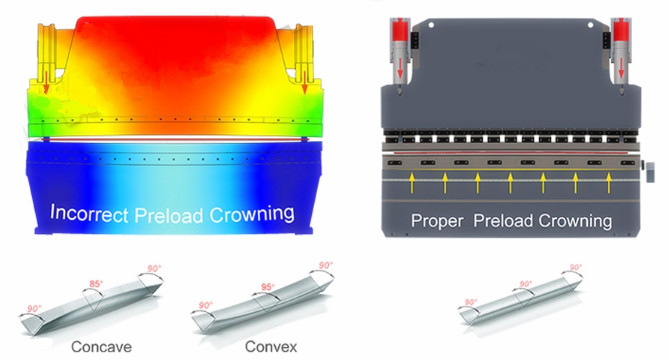

The crowning

The lower table is equipped with an automatic deflection compensation mechanism, and the compensation amount is automatically set by the numerical control system to ensure the uniform bending accuracy of the workpiece.

The workbench adopts unique design, which effectively reduces the deflection of the lower die.

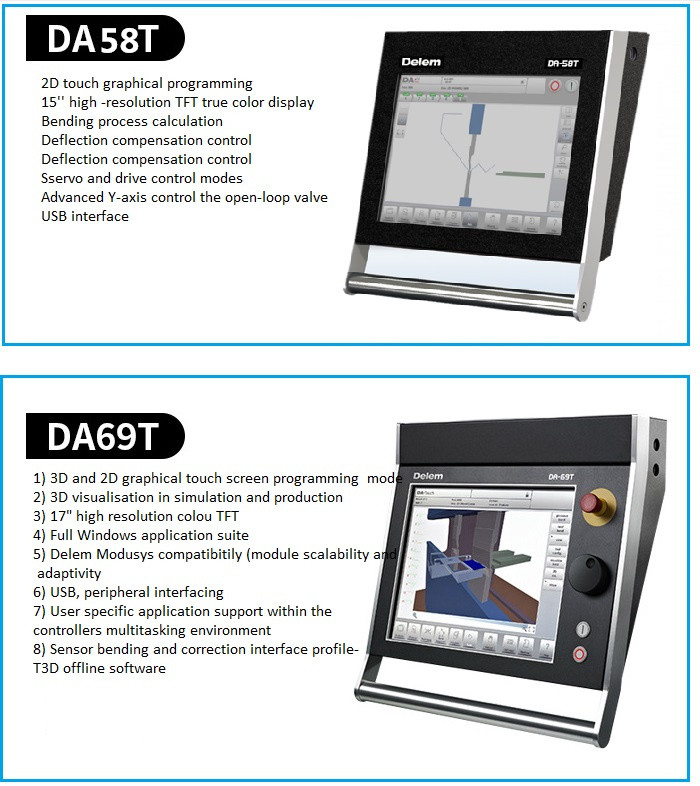

DA53T

Touch, making easy easier

The new compact DA-53T adds a state-of-the-art complete touch control solution for synchronized press brakes. Offering easiest CNC programming based on the Delem graphical touch screen user interface.

This panel based control, standard capable of controlling up to 4 axes, can be integrated in cabinets as well as used in an optional pendulant arm housing.

Its 10.1" wide screen high resolution colour TFT, with industrial grade multi touch technology, gives access to the proven Delem user-interface. It enables direct “hot-key” touch navigation between product programming and actual production. Functions are located where needed, offering optimised ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence.

Optional